Maker Space

Design and Development

Spring 2015

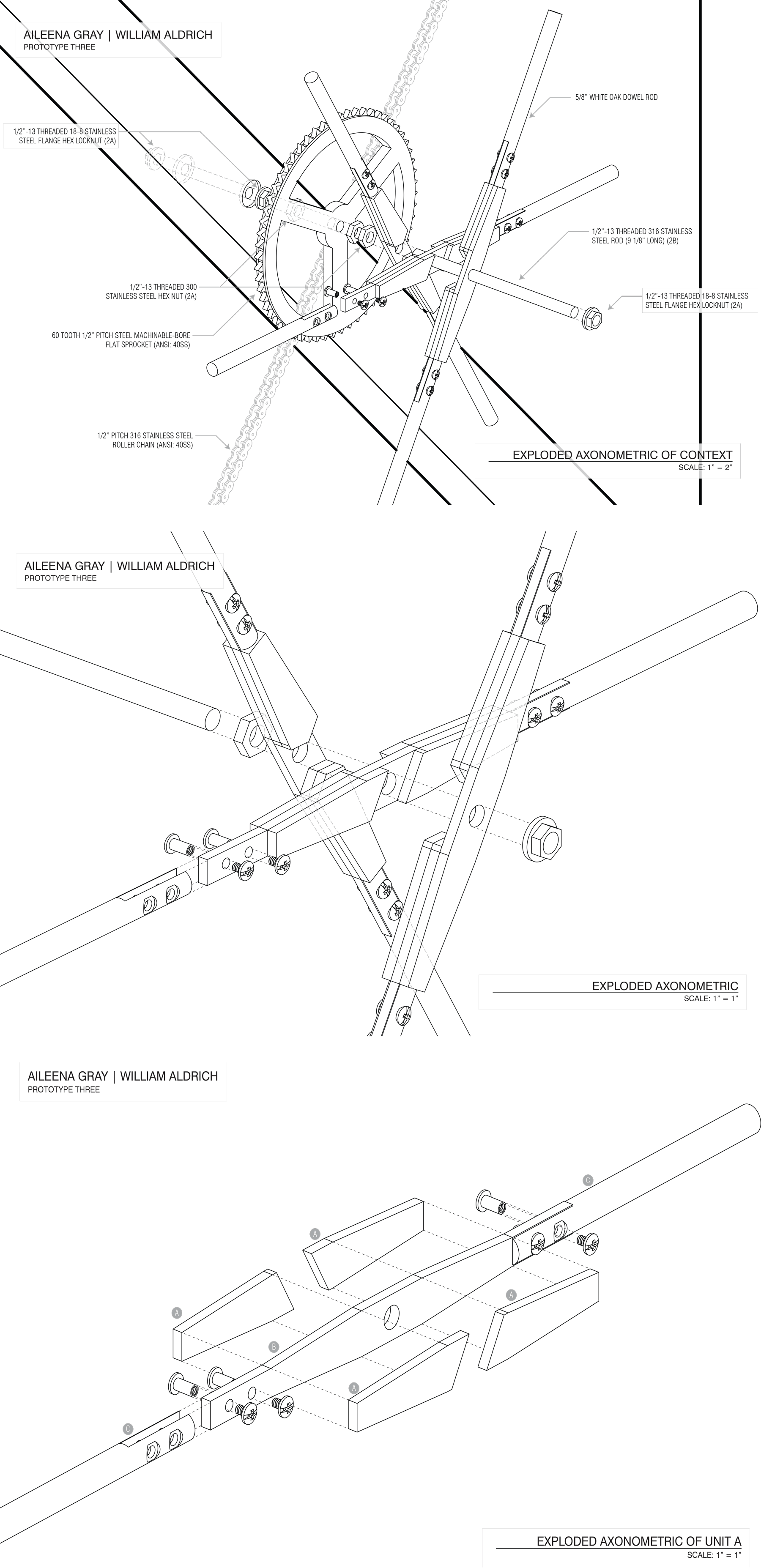

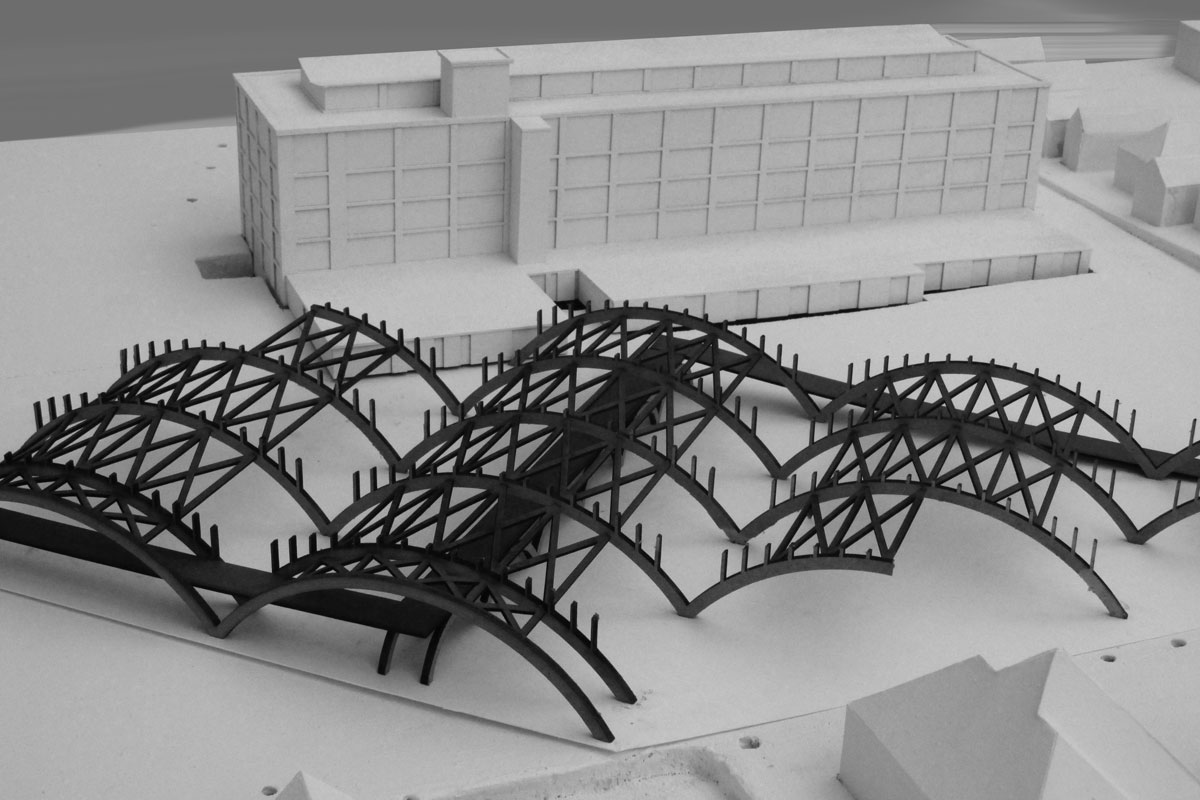

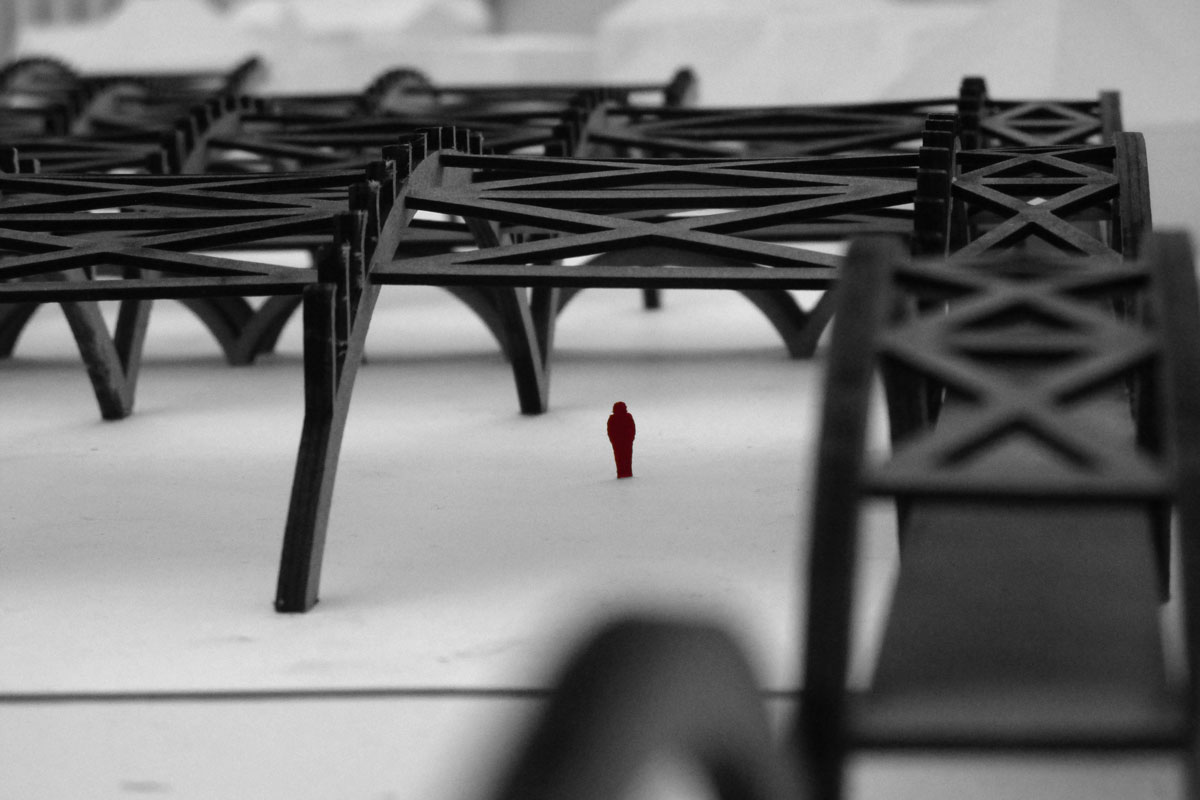

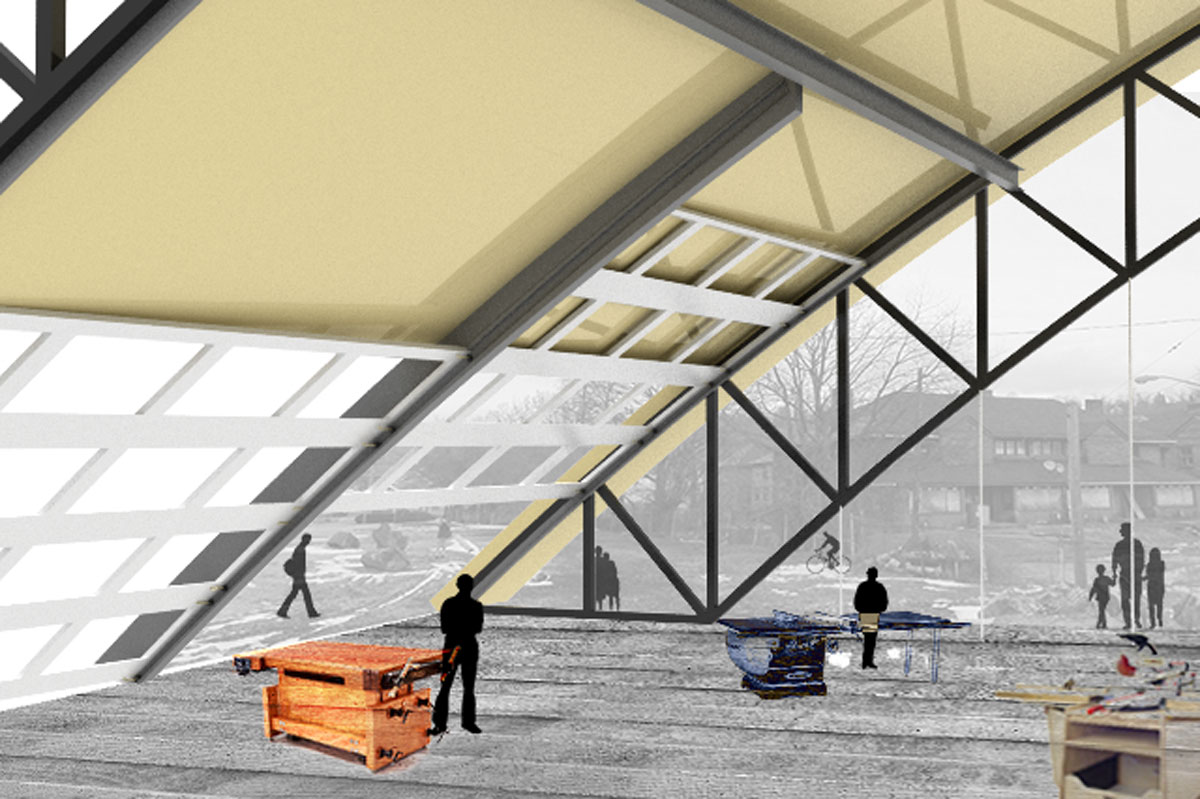

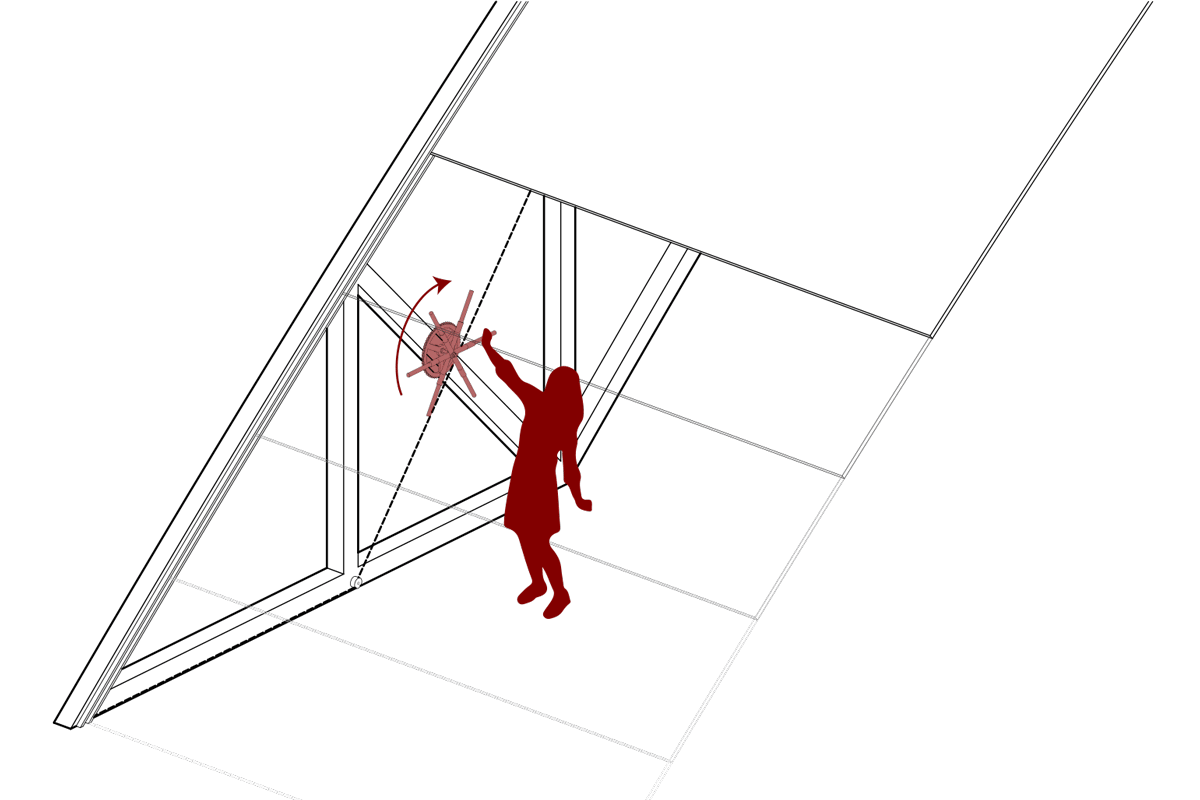

- A makerspace is a highly technical facility that offers collaborative work spaces in which the public can create and learn. During the second half of my third year, a partner and I designed such a space that could have the ability to also uplift a community. This project was also an exercise in detailing and prototyping: while desigining the building, we were tasked with creating a physical piece of the design through a fabricator in the Pittsburgh area.

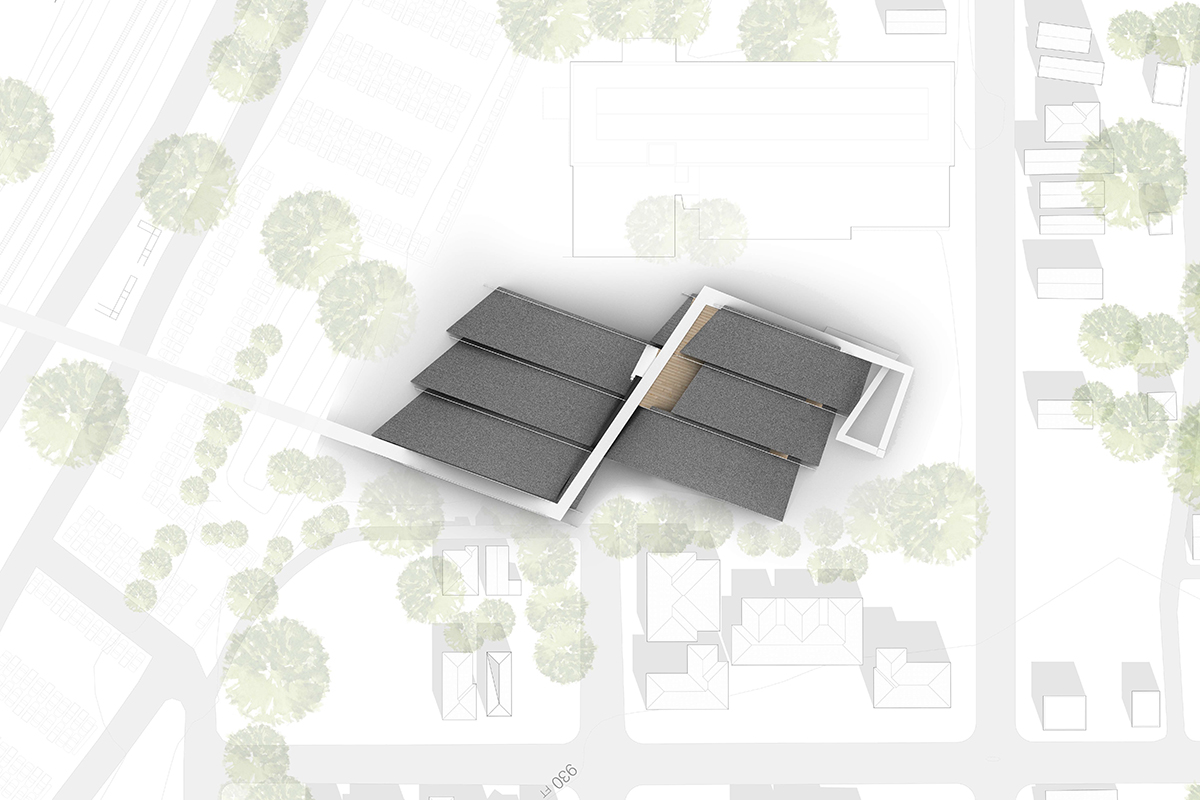

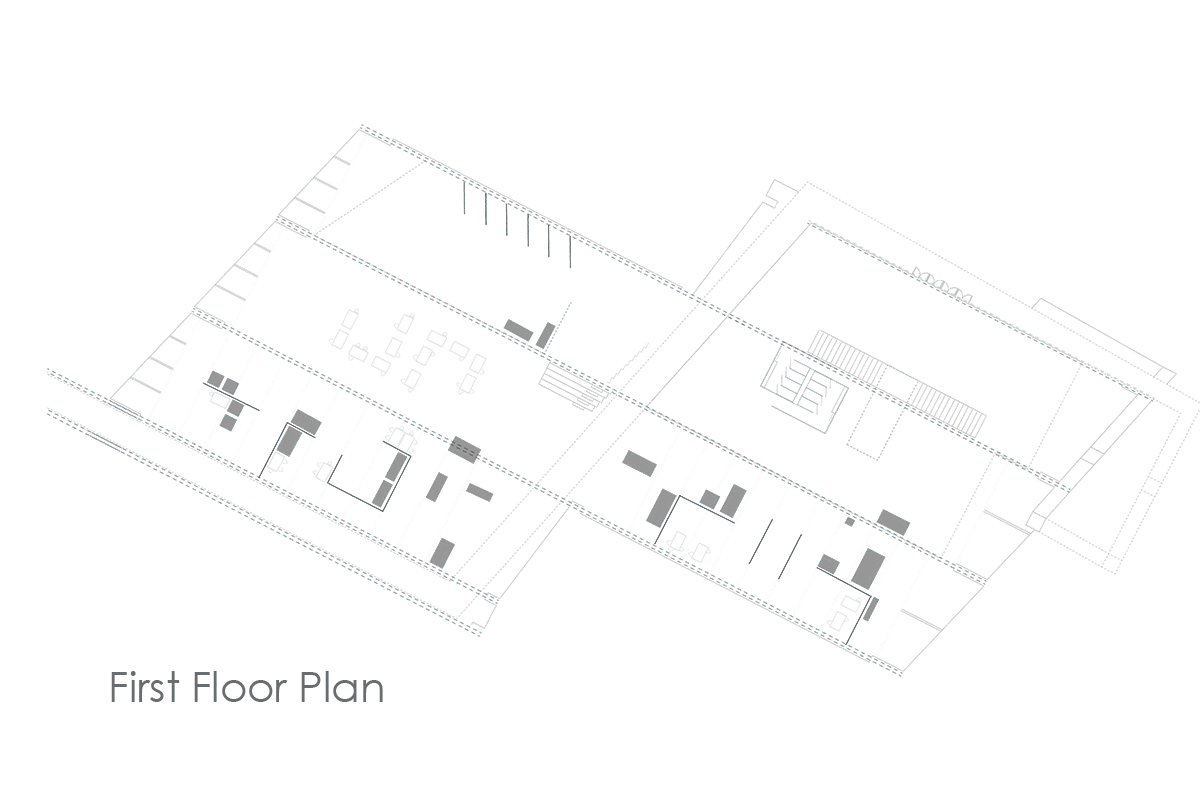

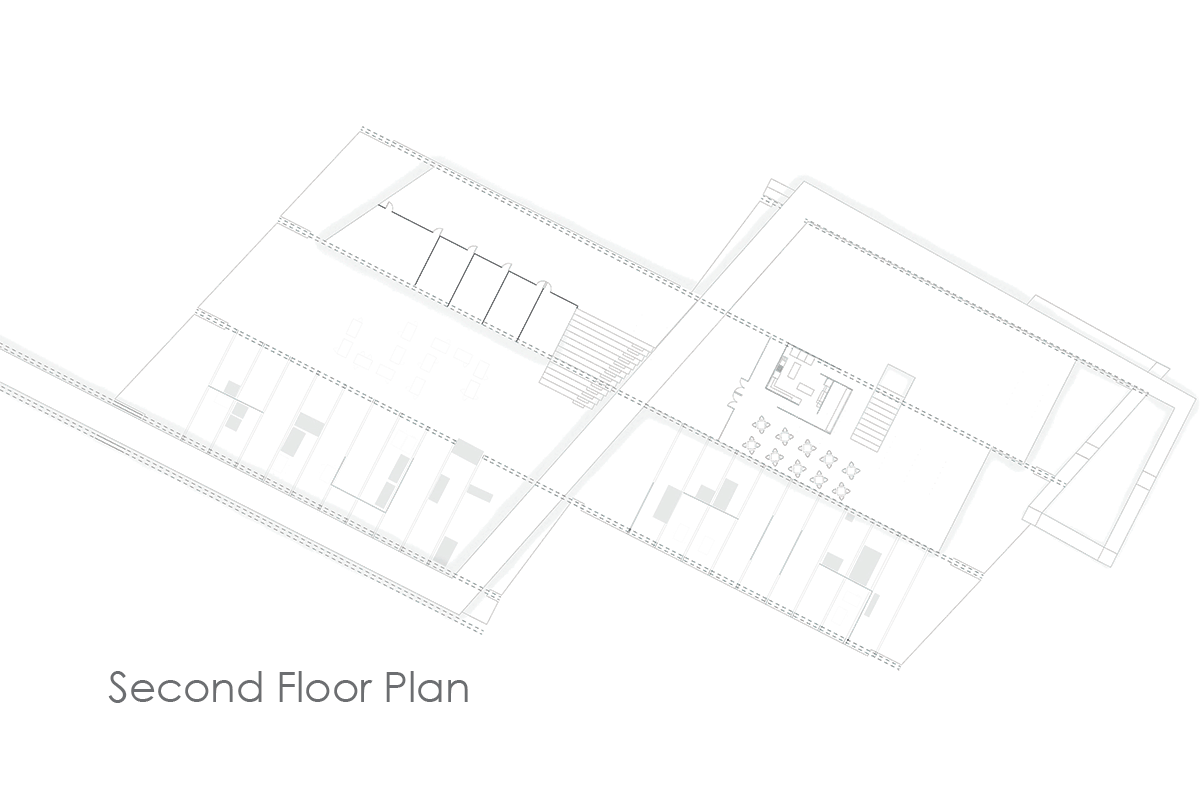

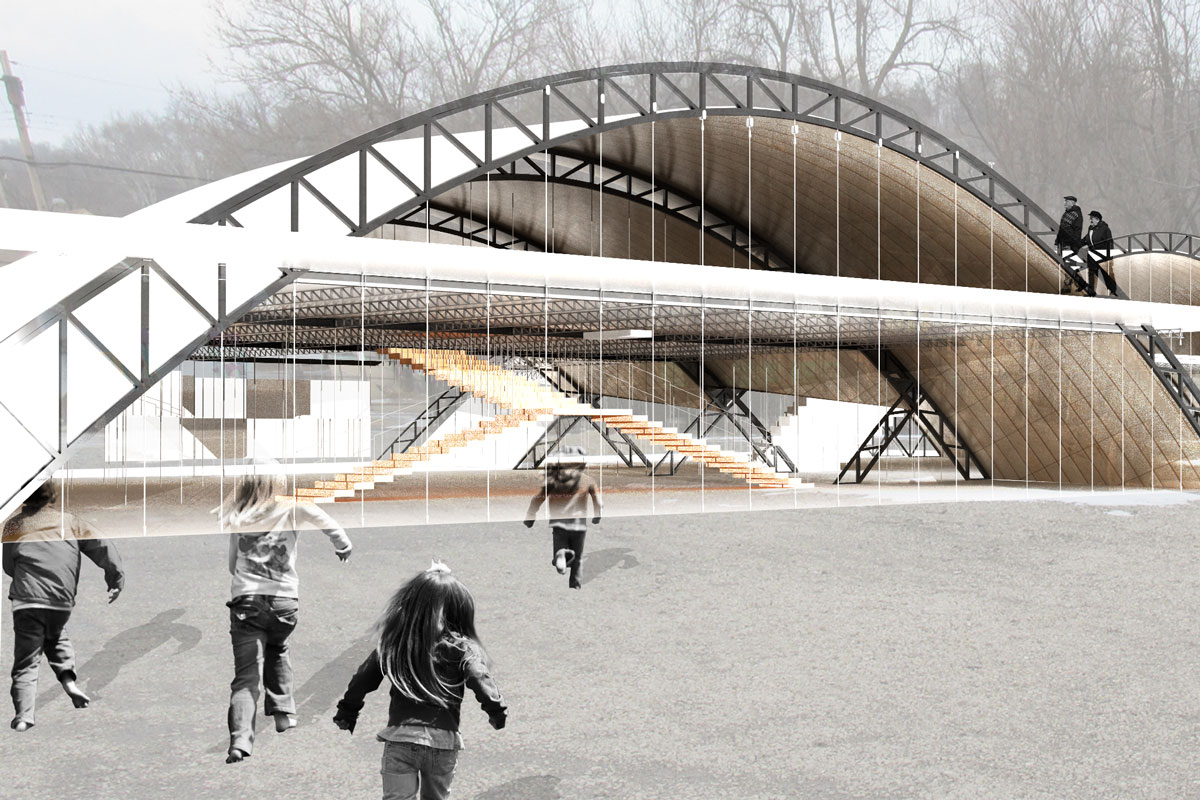

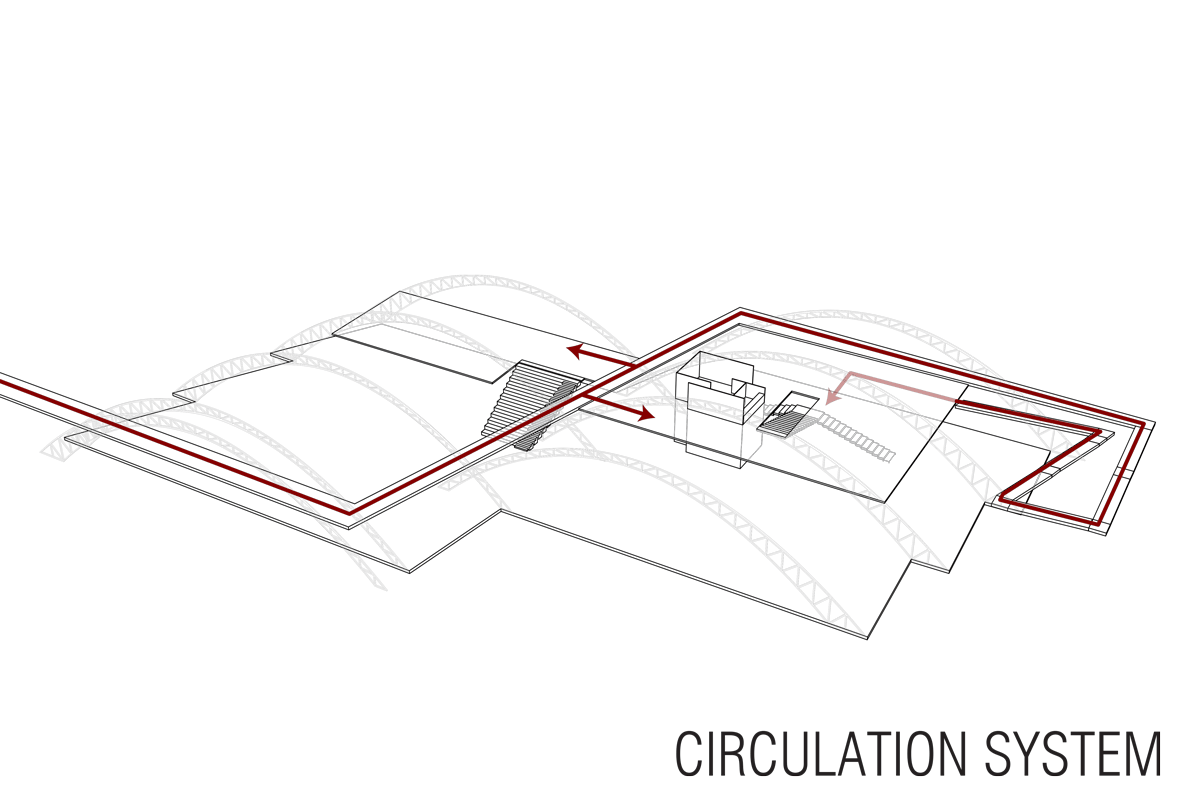

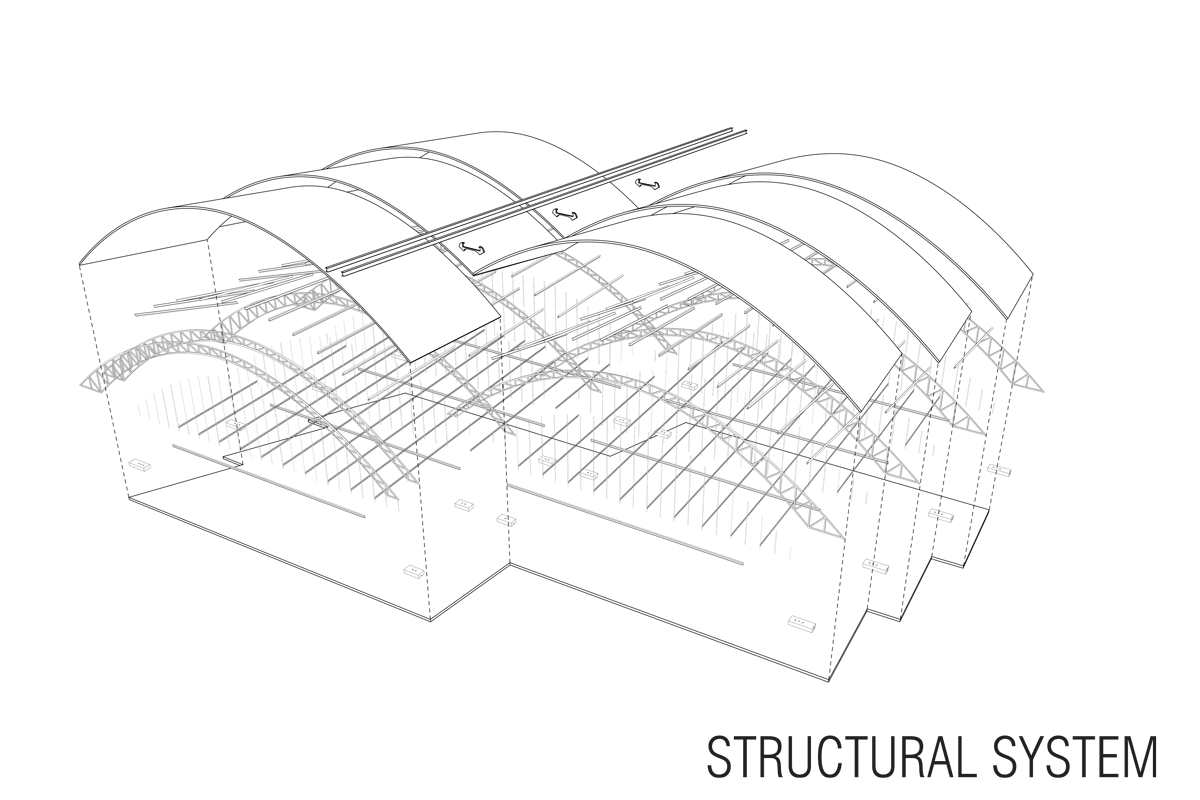

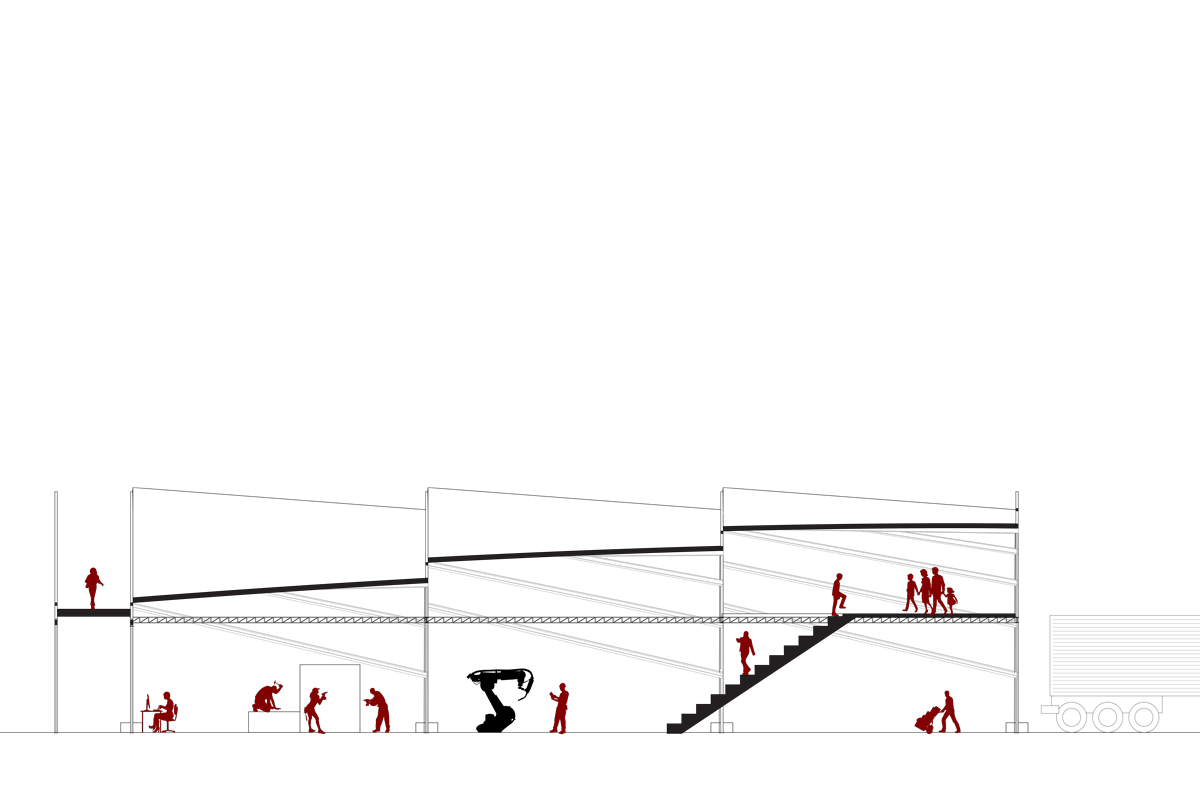

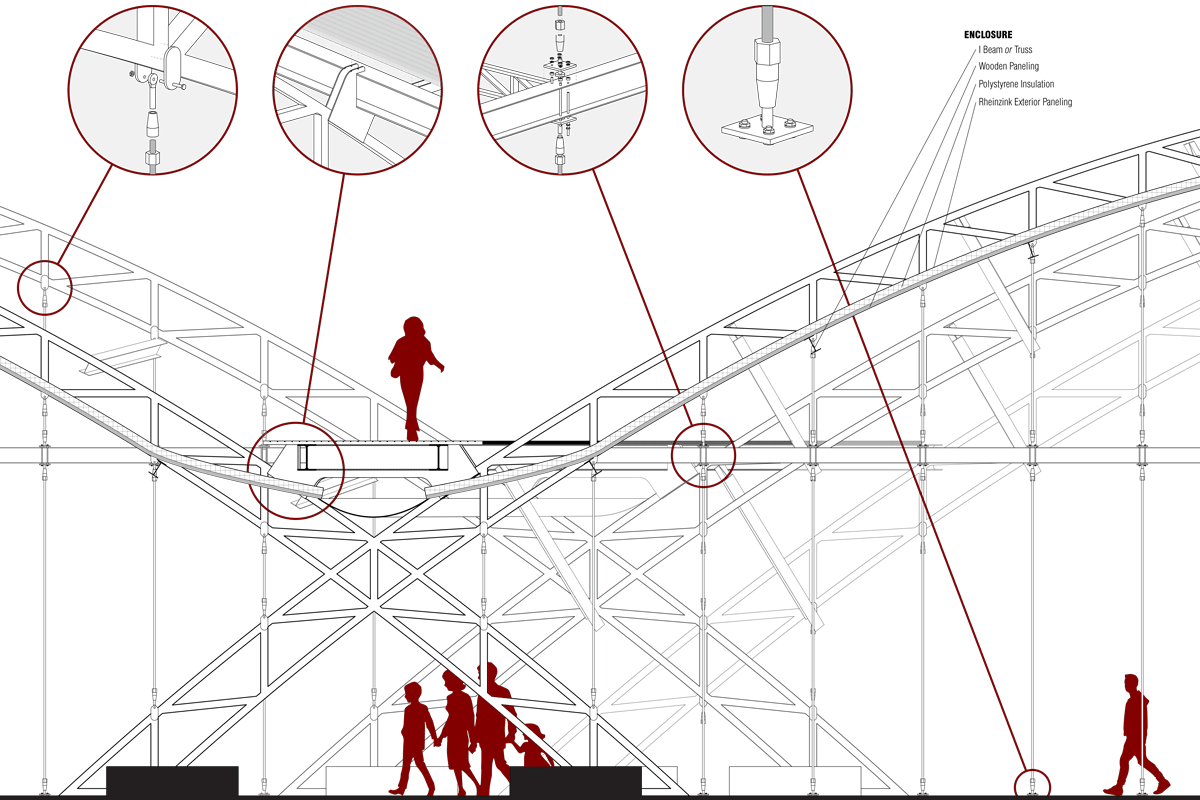

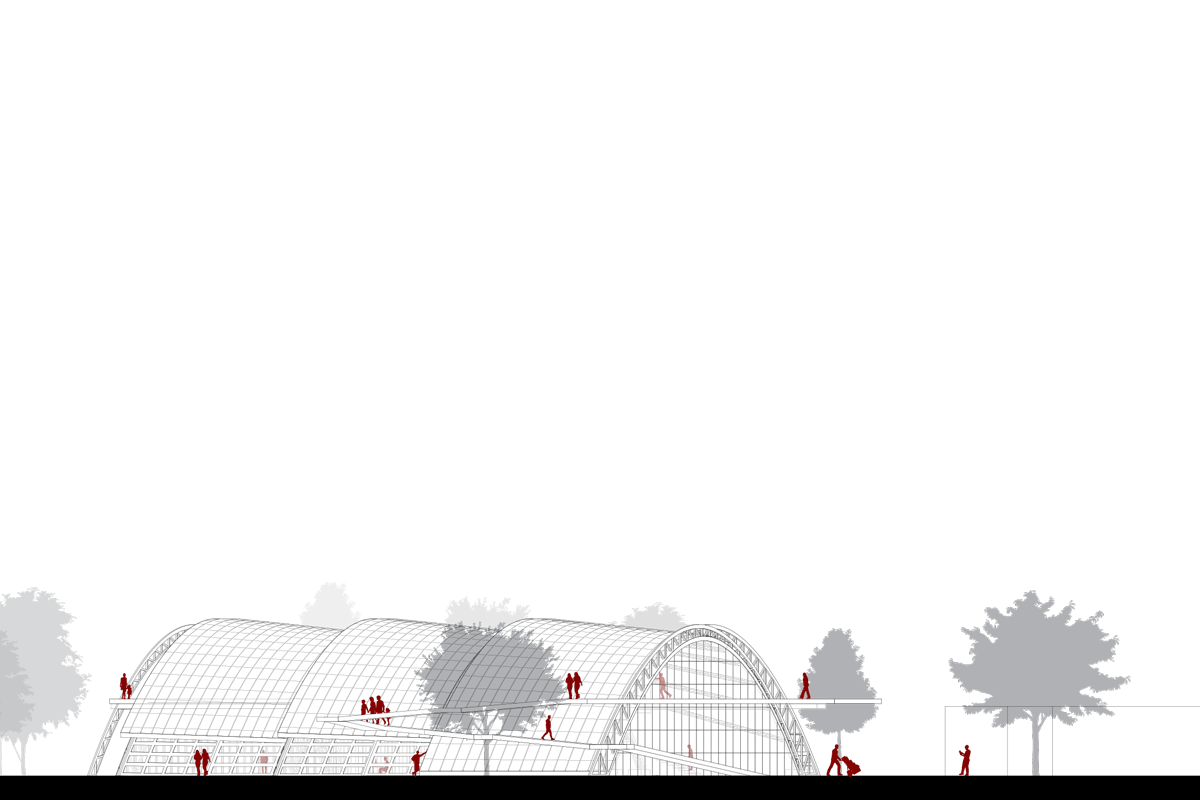

Our design included a bridge connecting the Homewood and Point Breeze communities that were separated by Pittsburgh's new bus route. The structure of the bridge became the element which drove the design of the entire building. Wide arches developed from trusses allowed for a very open plan, plenty of natural lighting (through the arches themselves), and a unique circulation pattern. it also provided a system with which the programmatic elements could be laid out. A system of beams connected the trusses structurally and held up a second floor in some parts of the building. Large amounts of glazing held up through tensioned cable and spider clamps created a disply of the interior.

In conjunction with Aileena Gray